Back to - Boosting Production efficiency

A pouch labeling machine is very beneficial in increasing efficiency in today's fast-paced production environments. They often handle 10-20 pouches per minute and, in the case of manual labeling processes, they can be particularly labor intensive and inconsistent leading to mistakes being made. By comparison, an automated pouch labeling machine can label 100 pouches per minute fairly accurately. This speed is essential for handling high order volume while still working with short shipping turnaround, making it an essential resource for businesses looking to grow their operations.

Making Sure Labels Are Both Accurate and Consistent

Label accuracy is not just a matter of aesthetics; it serves as the lifeblood for brand integrity and regulatory due diligence. Proper placement and accurate alignment of the label on a pouch is paramount for readability, the ability to be scanned, and for the overall look. This accuracy also reduces the risk of expensive mistakes like mislabelled products, which can then result in unhappy customers and even consumer recalls. This is combined with state-of-the-art technology in automated machines that are able to determine exactly where each pouch is situated, meaning that labels are applied in a consistent manner every time.

Reducing Operational Costs

It reduces the operational costs by minimizing the labor required as it can be an automated pouch labeling systemIntegrated with your packager system. Having a machine that does the labeling of pouches would allow businesses to reshuffle their workforce into something more strategic to boost productivity and decrease labor expenses. In addition, the accuracy of automatic labeling reduces the waste that arises when labels do not match or when the products have to be re-labeled, improving efficiency and reducing further costs.

Adaptability to Different Pouch Sizes and Materials

Modularity is definitely a highlight of modern-day pouch labeling machines. The machines are be capable to handled range of pouch sizes and materials(#) A pouch labeler machine can can be set up to work in conjunction with small sachets, large bags or different materials such as plastic, paper or foil. This suitability is due to their flexibility for industries like food and beverage, pharmaceuticals, and cosmetics, among others that have changing packaging formats.

Meeting LabelingFulfillment Standards

The need for label standards in industries is very observant with all the necessary details to be printed on the package of the product. With pouch labeling machines, these standards can be continually met with local and international, regulatory requirements and the device is tailored to apply labels that adhere to the set standards. Safety compliance is necessary for avoiding litigation and making your products commercially viable in different regions of the world.

Looking Forward

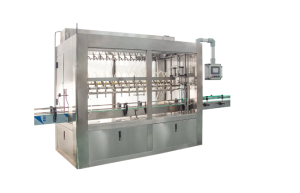

Image Source: The Bottom LineAlthough pouch labeling machines are indispensable in a PFM operation, they can integrate into your production line, vastly expanding what your operations can achieve in terms of efficiency, accuracy, and costs. The technologies like this helps to be compliant with the industry standards but also to improve the product presentation and customer satisfaction. Markets are always looking for faster and higher-strength packaging solutions, so a pouch labeling machine is an investment that will give a completely new view of their business future in a competitive environment.